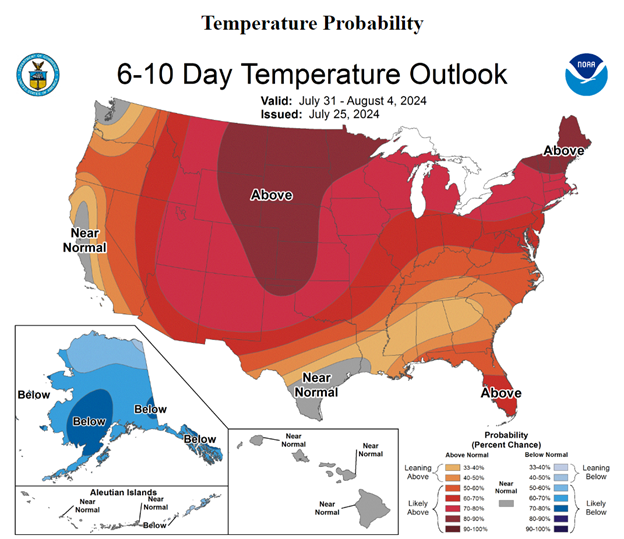

The National Weather Service compiled a list of resources on “Weather Information for Agriculture”. Direct links to long range outlooks (6-10 day and 8-14 day periods) for temperature are one inclusion which may be relevant for on-farm planning related to heat stress prevention.

The National Weather Service compiled a list of resources on “Weather Information for Agriculture”. Direct links to long range outlooks (6-10 day and 8-14 day periods) for temperature are one inclusion which may be relevant for on-farm planning related to heat stress prevention.

Farmers may utilize other tools referenced in this resource to:

- Evaluate recent precipitation and conduct monthly or seasonal reviews of precipitation

- Monitor current drought conditions

- View 1-7 day forecasts for severe weather, excessive rain, air quality, and other weather-related hazards

- Explore long-range outlooks (up to 3 months out) for temperature, precipitation, and drought

Article By: The Rutgers Farm Health and Safety Working Group: Kate Brown, Michelle Infante-Casella, Stephen Komar and William Bamka

The University of Houston Clear Lake, using grant funds from the Occupational Safety and Health Administration (OSHA), created a model

The University of Houston Clear Lake, using grant funds from the Occupational Safety and Health Administration (OSHA), created a model