- Cucurbit powdery mildew season is here. For a review of CPM control strategies please click here.

- Cucurbit downy mildew has been reported on cucumber in western MI and as far north as North Carolina on cucumber. For a review of CDM control please click here. To track the progress of CDM on your phone or PC please visit the CDM forecasting website.

- No reports of Late blight in region. To track the progress of Late blight in the US please click here.

- Basil downy mildew (BDM) has been reported in southern New Jersey on BDM susceptible sweet basil. All growers are encouraged to initiate preventative fungicide programs on DMR and non-DMR basil. For control options and to follow the progress of BDM in the US on your phone or PC please click here.

- Bacterial canker has been reported in fresh-market tomato. For a review of bacterial canker in tomato please see report by Dr. Sally Miller at The Ohio State University by clicking here.

- Diplodia leaf streak, a fungal disease, was identified in sweet corn this past week. Symptoms include the development of numerous pycnidia which produce conidia within the lesions on infected corn leaves. For nice reviews, please see report by Dr. Kiersten Wise and colleagues from the University of Kentucky and report by Dr. Steve Johnson at the University of Maine.

- White mold, caused by Stromatina cepivorum, has been reported in garlic. For more information, please see report by Crystal Stewart and Frank Hay from Cornell University.

- Angular leaf spot has been reported in summer squash. Look for angular lesions delimited by leaf veins and ‘shotholes’ in infected leaves that develop after periods of hot, dry weather.

- Phytophthora blight has been reported in pepper and cucurbit crops.

- Rhizoctonia and Pythium root rot have been reported in pepper. For a review of identifying and controlling root rots please click here.

- Septoria leaf spot and bacterial blight have been reported in parsley.

- Timber rot, or white mold, has been reported in tomato.

- White rust and Cercospora have been reported in spinach.

- Bacterial leaf spot has been reported in sweet basil. BLS of sweet basil is a relatively new disease of basil in the US. The bacterium has a large host range and can survive and overwinter in the soil on infested plant debris. Disease development is favored by hot, humid, rainy weather. Periods of hot, dry weather will help mitigate disease development.

- Sand blasting has been reported on a number of leafy green and other crops these past few weeks. Injury from sand blasting predisposes plants to bacterial infections. Remember, all bacteria need a wound or a natural opening, such as a stomata, to gain entry into the plant. Fields with extensive injury need to be scouted regularly, and most likely will need to be sprayed regularly with a copper fungicide or disinfectant-type product to help mitigate infection and spread.

- For a review on how to avoid sunscald injury on transplanted crops please click here.

- With the on and off again heavy rains we have been getting, along with warmer weather, all growers should consider applying at-transplanting fungicides for root rot control. Please click here to see these articles.

- The 2020/2021 Commercial Vegetable Production Recommendations Guide is available for free online! With many county offices running reduced hours or being closed this is the easiest way to obtain the newest recommendations.

- For a quick review on managing fungicide resistance development using tank mixes and fungicide rotations, and information on FRAC group 4, FRAC group 7, and FRAC group 3 and FRAC group 11 fungicides please click on hyperlinks.

Vegetable Crops Edition

Seasonal updates and alerts on insects, diseases, and weeds impacting vegetable crops. New Jersey Commercial Vegetable Production Recommendations updates between annual publication issues are included.

Subscriptions are available via EMAIL and RSS.

Quick Links:

NJ Commercial Vegetable Production Recommendations

NJ Commercial Vegetable Production Recommendations

Rutgers Weather Forecasting - Meteorological Information important to commercial agriculture.

Rutgers Weather Forecasting - Meteorological Information important to commercial agriculture.

Vegetable Disease Update – 6/26/20

IPM Update 6/24/20

Sweet Corn

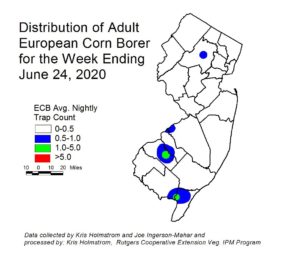

European corn borer (ECB) moth catches have declined somewhat over the past week. At this time, activity is highest in Gloucester County and along the Cape May/Cumberland bay shore (see ECB map at left). Catches are widely dispersed. Larval infestations above 20% continue into the northern counties this past week. Larval infestations should be expected to continue for approximately another 2 weeks.

European corn borer (ECB) moth catches have declined somewhat over the past week. At this time, activity is highest in Gloucester County and along the Cape May/Cumberland bay shore (see ECB map at left). Catches are widely dispersed. Larval infestations above 20% continue into the northern counties this past week. Larval infestations should be expected to continue for approximately another 2 weeks.

As always, look for the characteristic “shot-hole” type of feeding (photo below at right) and consider treating when infested plants exceed 12% in a 50 plant sample. As plantings proceed to the pre-tassel stage, ECB larvae may be found in emerging tassels (see photo at left). It is a good idea to treat individual plantings as they move into the full tassel/first silk stage one time. This eliminates any ECB larvae that have emerged with the tassels as they begin to move down the stalk to re-enter near developing ears.

Useful insecticides for this particular application include synthetic  pyrethroids (IRAC Grp 3), spinosyns (including OMRI approved Entrust) IRAC Grp 5), and diamides such as Coragen (IRAC Grp 28) or materials such as Besiege which include the active ingredient in Coragen. Synthetic pyrethroids alone should NOT be used for corn earworm (CEW) protection on silking corn. Control with these materials is very inconsistent.

pyrethroids (IRAC Grp 3), spinosyns (including OMRI approved Entrust) IRAC Grp 5), and diamides such as Coragen (IRAC Grp 28) or materials such as Besiege which include the active ingredient in Coragen. Synthetic pyrethroids alone should NOT be used for corn earworm (CEW) protection on silking corn. Control with these materials is very inconsistent.

The highest nightly trap catches of ECB for the week ending 6/24/20 are as follows:

| Downer 2 | Eldora 1 | Milltown 1 |

| Blairstown 1 | Farmingdale 1 | Port Colden 1 |

| Cinnaminson 1 | Lawrenceville 1 | Springdale 1 |

| Denville 1 | Matawan 1 | Tabernacle 1 |

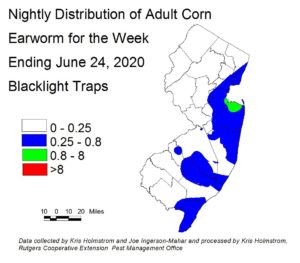

Corn earworm (CEW) moth captures increased slightly in blacklight traps this past week. As early plantings are now in the silk stage, they will need protection from this pest. Blacklight catches sere highest overall along the coast (see map at left).

Corn earworm (CEW) moth captures increased slightly in blacklight traps this past week. As early plantings are now in the silk stage, they will need protection from this pest. Blacklight catches sere highest overall along the coast (see map at left).

The highest nightly trap catches of CEW in black light traps for the week ending 6/24/20 are as follows:

| Matawan 2 | Elm 1 | New Egypt 1 |

| Bellemeade 1 | Green Creek 1 | Sergeantsville 1 |

| Crosswicks 1 | Hillsborough 1 | Springdale 1 |

| Eldora 1 | Milltown 1 | Tabernacle 1 |

Recorded Webinar Posted – COVID-19 Guidance for Ag Workers/Employers

- There have been no changes to the document since it was published, but one major point of discussion that you will hear in the recording was a comment made by a presenter that temperature monitoring should use a 99oF threshold instead of the 100.4oF threshold that was published in the guideline. Monique Purcell, Assistant Secretary of Agriculture, who had worked closely with the NJDOH and NJDOL reps in development of the guidance document received clarification from them the next day that confirmed that the threshold remains 100.4oF.

- The other point addressed by several speakers was the need to work with and invite the FQHCs to your farm. They are charged with helping to educate your farm workers to understand this disease, how it spreads, and how to protect themselves (the importance of physical distancing and wearing face masks), as well as to provide testing for all employees on your farm, including the owner and family members working on the farm, free of charge.

*The NJDOH partnered with the NJDA and the NJDOL to create this guidance for agricultural employers focusing on precautions to help protect farm employees from COVID-19 on New Jersey farms and in farm labor housing. This webinar reviews these guidelines.

IPM Update 6/17/20

Sweet Corn

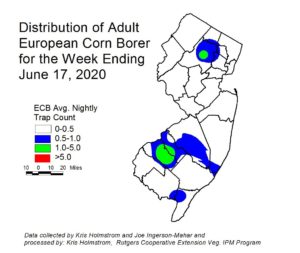

European corn borer (ECB) moth catches increased somewhat over the past week although higher numbers were recorded in a relatively low number of locations. At this time, activity is highest in Gloucester and central Morris counties (see ECB map at left). Catches remain widely dispersed. Larval infestations into the 30+% range were detected as far north as Morris County this past week. As moth catches begin to fall, larval development and damage increase. We expect that these infestation rates will continue to climb for the next 1-2 weeks in many parts of the state.

European corn borer (ECB) moth catches increased somewhat over the past week although higher numbers were recorded in a relatively low number of locations. At this time, activity is highest in Gloucester and central Morris counties (see ECB map at left). Catches remain widely dispersed. Larval infestations into the 30+% range were detected as far north as Morris County this past week. As moth catches begin to fall, larval development and damage increase. We expect that these infestation rates will continue to climb for the next 1-2 weeks in many parts of the state.

Look for the characteristic “shot-hole” type of feeding (photo below at right) and consider treating when infested plants exceed 12% in a 50 plant sample. As plantings proceed to the pre-tassel stage, ECB larvae may be found in emerging tassels (see photo at left). It is a good idea to treat individual plantings as they move into the full tassel/first silk stage one time. This eliminates any ECB larvae that have emerged with the tassels as they begin to move down the stalk to re-enter near developing ears.

Look for the characteristic “shot-hole” type of feeding (photo below at right) and consider treating when infested plants exceed 12% in a 50 plant sample. As plantings proceed to the pre-tassel stage, ECB larvae may be found in emerging tassels (see photo at left). It is a good idea to treat individual plantings as they move into the full tassel/first silk stage one time. This eliminates any ECB larvae that have emerged with the tassels as they begin to move down the stalk to re-enter near developing ears.

Useful insecticides for this particular application include synthetic  pyrethroids (IRAC Grp 3), spinosyns (including OMRI approved Entrust) IRAC Grp 5), and diamides such as Coragen (IRAC Grp 28) or materials such as Besiege which include the active ingredient in Coragen. Synthetic pyrethroids alone should NOT be used for corn earworm (CEW) protection on silking corn. Control with these materials is very inconsistent.

pyrethroids (IRAC Grp 3), spinosyns (including OMRI approved Entrust) IRAC Grp 5), and diamides such as Coragen (IRAC Grp 28) or materials such as Besiege which include the active ingredient in Coragen. Synthetic pyrethroids alone should NOT be used for corn earworm (CEW) protection on silking corn. Control with these materials is very inconsistent.

The highest nightly trap catches of ECB for the week ending 6/17/20 are as follows:

| Eldora 2 | Crosswicks 1 | Medford 1 |

| Allentown 1 | Denville 1 | New Egypt 1 |

| Blairstown 1 | Downer 1 | Springdale 1 |

| Cinnaminson 1 | Elm 1 | Tabernacle 1 |

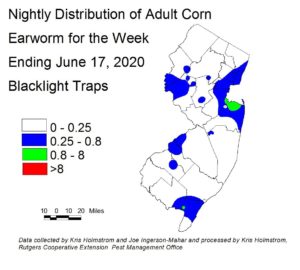

Increased catches of corn earworm (CEW) moths were recorded this past week. As early plantings proceed to full tassel and on to silk, they will need protection from this pest. Blacklight catches (see map at left) were scattered, but higher in locations than the previous week.

Increased catches of corn earworm (CEW) moths were recorded this past week. As early plantings proceed to full tassel and on to silk, they will need protection from this pest. Blacklight catches (see map at left) were scattered, but higher in locations than the previous week.

The highest nightly trap catches of CEW in black light traps for the week ending 6/17/20 are as follows:

| Matawan 3 | Clinton 1 | Hackettstown 1 |

| Asbury 1 | Downer 1 | Hillsborough 1 |

| Bellemeade 1 | Eldora 1 | New Egypt 1 |

| Cinnaminson 1 | Green Creek 1 | Springdale 1 |

USDA Good Agricultural Practices, Harmonized and Harmonized Plus Audits

Wes Kline reports the New Jersey Department of Agriculture is now scheduling audits.

- There had been an extension for audits before May 31, but there will be no additional extensions.

- If you had an audit last year and need to schedule a renewal, or if you need a new audit, now is the time to make an appointment.

- Anyone wanting an audit should have gone through food safety training which is held each year December through March. The auditor will want to see that you have had some type of training.

- To schedule the audit, email Chris Kleinguenther at christian.kleinguenther@ag.state.nj.us.

Tonight’s Webinar for Ag Employers – Updated Agenda

This event requires registration and there will be a follow-up survey.

- Rick VanVranken & Wes Kline, Agricultural Agents, Rutgers Cooperative Extension

- Secretary of Agriculture Doug Fisher, NJ Dept. of Agriculture

- Asst. Secretary of Agriculture Monique Purcell, NJDA

- NJ Dept. of Health

- Amanda Medina-Forrester, MA, MPH, Executive Director, Office of Minority & Multicultural Health &

- Siobhan Pappas, Ph.D., Coordinator, Childhood Lead Program

- NJ Dept. of Labor & Workforce Development

- Christine Blumauer, Policy Advisor, Office of the Commissioner

- Comments from Federally Qualified Health Center representatives

- Michelle Blanchfield, MPH, Zufall Health

- Bridget Hogan, Ocean Health Initiatives

- Pete Furey, Exec. Director, NJ Farm Bureau

The NJDOH partnered with the NJDA and the NJDOL to create this guidance for agricultural employers focusing on precautions to help protect farm employees from COVID-19 on New Jersey farms and in farm labor housing. This webinar will review these guidelines. Questions from participants will be taken and addressed during the webinar.