The FDA Food Safety Modernization Act (FSMA) Produce Safety rule is now final, and the earliest compliance dates for some farms begin one year after the effective date of the final rule (see “Compliance Dates” below). The rule establishes, for the first time, science-based minimum standards for the safe growing, harvesting, packing, and holding of fruits and vegetables grown for human consumption. The FDA has created a factsheet highlighting the produce safety rule.

The FDA Food Safety Modernization Act (FSMA) Produce Safety rule is now final, and the earliest compliance dates for some farms begin one year after the effective date of the final rule (see “Compliance Dates” below). The rule establishes, for the first time, science-based minimum standards for the safe growing, harvesting, packing, and holding of fruits and vegetables grown for human consumption. The FDA has created a factsheet highlighting the produce safety rule.

This rule was first proposed in January 2013. In response to input received during the comment period and during numerous public engagements that included public meetings, webinars, listening sessions, and visits to farms across the country, the FDA issued a supplemental notice of proposed rulemaking in September 2014. The proposed revisions were designed to make the originally proposed rule more practical, flexible, and effective.

The final rule is a combination of the original proposal and revisions outlined in the supplemental proposal, with additional changes as appropriate. The definition of “farm” and related terms were revised in the final Preventive Controls for Human Food rule, and the same definitions of those terms are used in this rule to establish produce safety standards. Operations whose only activities are within the farm definition are not required to register with FDA as food facilities and thus are not subject to the preventive controls regulations.

[Read more…]

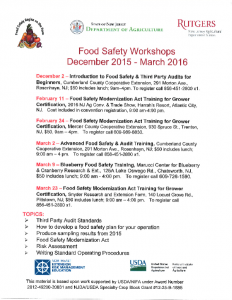

The harmonized audit requires a listing of equipment (2.7.1) that has the potential to come into contact with the crop, and for each piece of equipment a maintenance record.

The harmonized audit requires a listing of equipment (2.7.1) that has the potential to come into contact with the crop, and for each piece of equipment a maintenance record.