Vegetable Crops Edition

Seasonal updates and alerts on insects, diseases, and weeds impacting vegetable crops. New Jersey Commercial Vegetable Production Recommendations updates between annual publication issues are included.

Subscriptions are available via EMAIL and RSS.

Quick Links:

NJ Commercial Vegetable Production Recommendations

NJ Commercial Vegetable Production Recommendations

Rutgers Weather Forecasting - Meteorological Information important to commercial agriculture.

Rutgers Weather Forecasting - Meteorological Information important to commercial agriculture.

COVID-19: PESTICIDE EXAMS CANCELLED **NJDEP ALERTS **

INSECTICIDES FOR MANAGING PEPPER WEEVIL

In light of the review of the neonicotinoid insecticides by the Environmental Protection Agency (EPA), it is worthwhile to review insecticidal options if the EPA follows through with its interim recommendations for the neonicotinoid insecticides thiamethoxam, imidacloprid, and dinetofuran.

The proposed recommendation is that these materials may not be used on fruiting vegetables after 5 days post transplanting until the end of blooming. If this recommendation is finalized then the use of Actara, Admire Pro, and Scorpion will not be allowed during crucial growth stages for protecting against, or, suppressing pepper weevil populations.

In recent years, insecticide trials conducted in Florida and California have shown that the products Harvanta, Rimon, Torac, and Vydate L provide the best management of pepper weevil aside from the neonicotinoids. Generally, pyrethroids ((Warrior, Tombstone, etc.) IRAC # 3A) are not recommended unless they are used in rotation with other IRAC group insecticides. It should be noted that under heavy pressure no insecticide will be effective in reducing the weevil population.

Especially for those pepper fields in high-risk areas near processing plants or landfills that accept vegetable waste, an insecticide should be applied to transplants as soon as they begin to bloom and set fruit.

The following is a partial list of registered materials in New Jersey labeled for pepper weevil:

Active ingredient IRAC # Product

oxamyl 1A Vydate L

acetamiprid 4A Assail

novaluron 15 Rimon

tolfenpyrad 21A Torac

cyantraniliprole 28 Exirel

cyclaniliprole 28 Harvanta

For a complete list of insecticides that are registered for managing pepper weevil in New Jersey go to http://www.kellysolutions.com/NJ/pesticideindex.asp

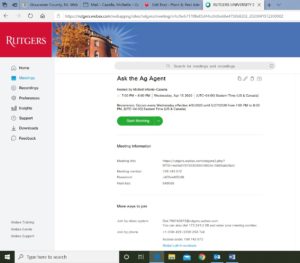

“Ask the Ag Agent” 7:00PM Weekly – Every Wednesday – Farmer Video Conference/Call-In Forum

By, William Bamka, Stephen Komar, Michelle Infante-Casella and Meredith Melendez

“Ask the Ag Agent” weekly 1-hour sessions for farmers will be hosted by Rutgers Agricultural Agents working with commercial farmers, on Wednesday April 15th and continue each Wednesday. The online conferencing/call in events will begin at 7:00PM with an open forum to discuss ag-related questions about production, marketing, regulations and any other topics farmers wish to discuss. All are welcome.

To access via WebEx on a computer go to https://go.rutgers.edu/rc9n3kxt

Join by phone

+1-650-429-3300 USA Toll

Access code: 799 743 872

New Requirements for Continued Registration of Paraquat

Pesticide Storage Inventory Due May 1st: Download Rutgers Templates

Marketing Tip: Consider Pre-Bagging Produce at Farm Markets

By, Michelle Infante-Casella and Meredith Melendez, Agricultural Agents

Farm marketers can learn from recent behaviors observed in supermarkets and other food outlets as we start the produce season in New Jersey. Besides facilitating social distancing and having employees and customers wear masks and other protective gear, farm owners and workers can help ease shopping anxiety by pre-bagging items.

To date there is no scientific evidence to support the transmission of COVID-19 through food, but customer buying patterns have shown that packaged produce is selling better than loose produce. Customers are fearful of virus transmission from many different sources regardless of the science. Most people are very suspicious when touching every object around them whether it be door handles, shopping carts, checkout counters, credit card machines and also on the list – loose fruits and vegetables on shelves that may have been handled by other people. These fears are certainly understandable.

Some food stores are reporting bagged items are selling faster than loose items. The public sentiment is wrapped produce has a barrier that acts as a safety measure against contamination. Produce items in pre-packaged containers, such as bagged lettuces, bagged broccoli, bagged cucumbers, bagged peppers, packaged tomatoes and other items wrapped in plastic have increased in sales over their unpackaged counterparts. In addition, items in highest demand tend to be more shelf-stable produce like potatoes, apples, onions, unpeeled carrots, winter squashes and cabbage.

The media has been publicizing milk dumping from tanker trucks, in-season produce fields being plowed, and issues with food distribution across the country due to issues from COVID-19. Consumers are questioning many issues right now. Is the U.S. food supply safe? Will there be enough food to go around? Will the food stores be closing? Is it safe to buy fresh produce? Should I worry when I see empty store shelves?

To ensure a domestic food supply in the future, it is more important than ever for customers to buy local and US farm products. This is a message the entire agriculture industry can share with the public.

Some questions about food and COVID-19 can be answered by reading the U.S. Food & Drug Administration’s website https://www.fda.gov/food. This is also a good site to send your customers to help answer their questions. Resources specific for the agricultural community are listed on the Rutgers On-Farm Food Safety COVID-19 website.

In summary, farm market proprietors may want to keep produce displays well stocked with plenty of bagged and packaged produce items. This will also help facilitate having customers in the market for shorter periods. Customers can just pick up bags and go rather than pick through a pile and taking extra time to bag their own items. In addition, pricing bags ahead of time, that don’t need to be weighed, can also quicken check out times. Shoppers are in a hurry to get in and out of stores to ease fears of potential virus transmission. Making it as easy as possible to help facilitate shopping and check out may go a long way to lessen customer anxiety in current times. Keep engaged with customers for suggestions on what they may need from your market.

Farmers and farm markets will be playing a major role in food distribution and food security in the near future and beyond. Thank you to all farmers, farm workers, and other essential workers in this time of crisis.