Penn State Cooperative Extension is hosting a free webinar to discuss the H-2A program in Pennsylvania. This may be helpful for NJ Farmers to listen in to find any updates or tips on how to handle this agricultural worker program. You must register to join this online event. In order to register you will need to create an account on the Penn State advertisement page.

Webinar Date: Thu., May 7, 2020

(6:30 PM – 8:00 PM ET)

Registration deadline: May 7, 2020

5:30 p.m.

COVID-19 mitigation efforts, including international travel restrictions and consulate closures, have disrupted the normal functioning of the H-2A visa program for temporary workers. These disruptions to the H-2A program raise questions about the timely arrival of guest workers and the impact on essential food and agricultural businesses. The H-2A Agricultural Workers in Times of Uncertainty Webinar will provide answers and guidance to the many questions surrounding this topic.

The dangers of COVID-19 itself similarly raises questions around how to protect the health and well-being of H-2A visa holders. As front-line workers, the protection of their livelihoods and health are integrally tied to the protection of public health.

Penn State Extension will be holding a townhall-style webinar to address these topics, and to provide answers and guidance to these questions. Join us as we hear from a panel of subject matter experts, including Brook Duer, Staff Attorney at the Penn State Center for Agricultural and Shale Law; Grant Meckley, Pennsylvania Keystone Health’s Agricultural Worker Program; Scott Sheely, Executive Director of the Lancaster County Agriculture Council; and Richard Stup, Agricultural Workforce Specialist at Cornell Cooperative Extension. Also joining us will be Alyssa Charney, Agriculture Legislative Assistant from Senator Casey’s Office.

Attendees will have the opportunity to either send in questions ahead of time, or during the webinar itself, for a Q&A session following the panelists’ overview and update on the H-2A visa program.

There is no cost for this webinar, however registration is required to receive the webinar link. To go to the registration page you can also see https://go.rutgers.edu/if9tsm4h.

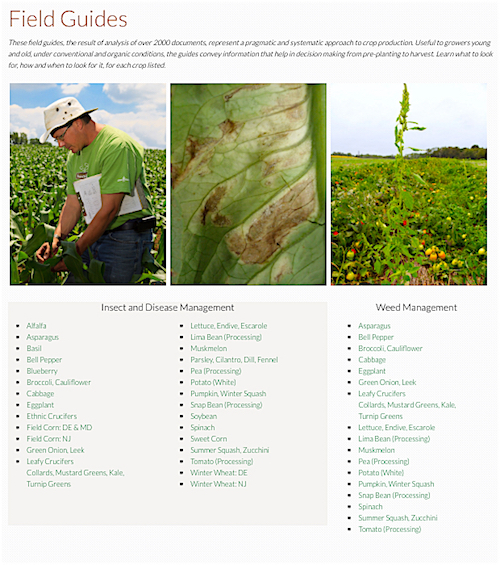

Articles in this section contain information helpful to the NJ commercial organic grower.

Articles in this section contain information helpful to the NJ commercial organic grower.

ertain time together.

ertain time together.