- With the on and off again rains we have been getting, along with warmer weather comng in later this week, all growers should consider applying at-transplanting fungicides for root rot control. Please click here to see this article.

- Transplant producers need to remember to regularly vent their structures to reduce relative humidity buildup going into the evenings to help reduce leaf wetness during the overnight and to manage their watering schedules.

- For the updated list of fungicides for use in the control of important diseases in the greenhouse please click here.

- Scouting and controlling Septoria leaf spot in parsley.

- Bacterial leaf blight in Cilantro was reported in southern New Jersey.

- Cold weather injury has been reported in numerous vegetable crops throughout the state.

- Common leaf spot was reported in strawberry. For more information click here. Weather conditions have also been ideal for fruit rot infections. For more information on controlling fruit rots in strawberry please click here.

- The 2020/2021 Commercial Vegetable Production Recommendations Guide is available for free online! With many county offices running reduced hours or being closed this is the easiest way to obtain the newest recommendations.

- For a quick review on managing fungicide resistance development using tank mixes and fungicide rotations, and information on FRAC group 4, FRAC group 7, and FRAC group 3 and FRAC group 11 fungicides please click on hyperlinks.

Vegetable Crops Edition

Seasonal updates and alerts on insects, diseases, and weeds impacting vegetable crops. New Jersey Commercial Vegetable Production Recommendations updates between annual publication issues are included.

Subscriptions are available via EMAIL and RSS.

Quick Links:

NJ Commercial Vegetable Production Recommendations

NJ Commercial Vegetable Production Recommendations

Rutgers Weather Forecasting - Meteorological Information important to commercial agriculture.

Rutgers Weather Forecasting - Meteorological Information important to commercial agriculture.

Vegetable Disease Update – 5/12/20

Frost Advisory in Effect Monday May 11 through Thursday May 14, 2020

Frost Advisory in Effect Monday May 11 through Thursday May 14, 2020.

A frost advisory is in effect for parts of Northern New Jersey for the nights of Monday May 11, Tuesday May 12, and Wednesday May 13 with temperatures at or below freezing predicted. Please take appropriate measures to protect tree fruit, grapes, strawberries and other small fruit.

Below are resources for determining the critical temperatures for tree and small fruit. Note that the critical temperature for damage at a particular bud stage may vary by 4 or 5⁰F depending on temperatures during the previous few days before the cold event.

Tree Fruit

Please note the PPA post from May 6, 2020 “Frost Protection in Orchards – What Should You Monitor?“

Note the critical temperature for some of the most common pome and stone fruit crops In New Jersey is available at:

https://www.canr.msu.edu/news/critical_spring_temperatures_for_tree_fruit_bud_stages.

Additional information on frost protection methods is available at:

Small Fruit

Frost and Freeze Damage on Berry Crops

Kathy Demchak Senior Extension Associate Penn State University

Here is a review of critical temperatures for damage to berry crops, symptoms of the damage, and some key points regarding protecting plants.

Critical Temperatures for Blossoms

Damage to blossoms is the biggest concern; critical temperatures are those at which you can expect damage to occur. Air temperature close to the ground is often much colder (as much as 5°F) than the low temperature reached at the typical eye-level height where we usually post our thermometers, and if your field is in a low spot, may be even colder. We also need to factor in the fact that the blossoms radiate heat into the sky (called radiational cooling), much like your vehicle roof that may have frost on it on the mornings when the low temperature didn’t reach freezing. Of course, low temperatures in any out-of-town rural location are often quite a lot lower than those forecasts; some growers subscribe to services that forecast more accurately for their specific location.

Critical temperatures for strawberry blossoms

For strawberries, critical temperatures for flower buds are 10° when just emerging from the crown, 22° when blossoms are emerged but still tightly closed, 26° when closed but petals are visible (“popcorn” stage), and 30° when open. Young green fruit is actually better able to tolerate cold temperatures than open blossoms, having a critical temperature of 28°. Some recommend actually inserting a thermocouple into the flower buds to most accurately measure their temperatures. Just propping up a thermometer at the end of the row so it’s exposed to air on all sides and radiates heat like a blossom would have mirrored the temperatures at which we get damage quite well. Frost-damaged blossoms will have a black center.

Critical temperatures for blueberry

Blueberry blossoms can tolerate colder temperatures than strawberry blossoms. Different sources give somewhat different values for certain stages, so ranges are given here. Critical temperatures are 15-20° at bud swell; 18-23° when flower clusters are still tight; 22-25° when flowers buds in the cluster have separated; 25-26° when flowers are still closed but full-size; and 27° for open blossoms. The stage where the petals have just fallen off is actually the most tender, with a critical temperature of 28°. Petals will turn brown if damaged, and fruit tissue inside the blossom will have a water-soaked appearance.

Critical temperatures for raspberry blossoms

We never used to mention frost damage on raspberries as a possibility, since raspberries typically bloom so late that we are usually past danger of frost by the time they bloom. However, in two out of the past ten years, we had frost damage to open raspberry blossoms; this occurred when temperatures were barely below freezing, which makes me think that the critical temperature is in the 30-32° range. Frost damaged blossoms on raspberries turn black in their center, but this is a little less obvious than on strawberries because the anthers extend beyond the damaged portion.

Frost Protection Methods

For berry crops, frost protection methods consist of either applying water with overhead irrigation or using row covers, or a combination of the two. Other methods such as wind machines and under-canopy irrigation don’t typically provide enough protection for berries or can’t be used due to plant architecture.

Frost protection using overhead irrigation

The theory behind why overhead irrigation works for frost protection is that heat is released as the water freezes (144 BTUs per pound of water), so the blossom temperature stays at 32°. The water application rate must be sufficient to keep a layer of liquid water on the ice that is forming, and coverage must be fairly even. If water completely freezes before additional water is applied by the next sprinkler rotation, heat is no longer being released by the freezing process.

This means that blossom temperatures can drop to ambient air temperature instead of being kept at 32°. When coverage is uneven or it is windy (more than about 3 mph), the application pattern is uneven, and you have more heat loss from evaporation than usual, so you are likely to have more damage than if you had done nothing at all. Irrigation should be kept running in the morning until ice starts to melt from the plants.

Frost protection using overhead irrigation

The theory behind why overhead irrigation works for frost protection is that heat is released as the water freezes (144 BTUs per pound of water), so the blossom temperature stays at 32°. The water application rate must be sufficient to keep a layer of liquid water on the ice that is forming, and coverage must be fairly even. If water completely freezes before additional water is applied by the next sprinkler rotation, heat is no longer being released by the freezing process.

This means that blossom temperatures can drop to ambient air temperature instead of being kept at 32°. When coverage is uneven or it is windy (more than about 3 mph), the application pattern is uneven, and you have more heat loss from evaporation than usual, so you are likely to have more damage than if you had done nothing at all. Irrigation should be kept running in the morning until ice starts to melt from the plants.

Keep in mind that you will need to allow time for the irrigation system to fully wet the plants, and there will be evaporation from the water than will lower the plant temperature at first; for this reason, we generally recommend starting the irrigation when the air temperature is 4° above the critical temperature. Of course, if the low temperature is forecasted to occur very late in the overnight hours and is close to the critical temperature, you will need to judge whether it is worth starting irrigation up or not.

Frost protection using row covers

Row covers can be effective, but they work best on still nights and when you only need 3 or 4° of frost protection. A row cover that is fairly stiff so it doesn’t cling to the plants and ground and maintains some air space works best; clingy ones may not provide much protection. There is one particular 1.25 oz/sq. yd. fabric that works well. It is more expensive than others but has a long field life, so it can be used for multiple seasons and is less expensive in the long run.

Row covers should be pulled over the field during the afternoon to allow some heat buildup under the cover. If it is windy, protection will be less, and if winds are over 5 mph or so, you may not get any protection at all. If you have an old row cover, it can be applied as a second layer underneath the newer cover – this helps on very cold nights and also helps to some degree on windy nights.

Recently there have been some questions regarding whether anthracnose can survive on row covers. One study showed that spores can survive on fabric (in the study’s case, denim) for 5 weeks. However, typically row covers aren’t still being used when anthracnose lesions are present in PA, but if they are, this may be a concern.

Overhead irrigation – row cover combination

We have had very good results with pulling on row covers and then irrigating over top of them for frost protection. Depending on the night, this has resulted in needing no overhead irrigation at all or delaying the time that we needed to start the irrigation since the temperature under the row cover is higher than the outside temperature, and water use is greatly decreased. You’ll want to pull the row covers back off as soon as you can the next day though to allow the plants to dry, otherwise, it will likely get steamy under the row cover, increasing the possibility of disease issues.

Frost Damage to Vegetative Tissues

Vegetation on small fruit crops is quite hardy in the spring. New vigorously growing raspberry canes can get “nipped” however, sometimes seriously. I can think of two instances when this happened with ours. Once was about 20 years ago when we hit 16° in mid-April when the new canes were about a foot tall, and the second time was about in 2012 when raspberries in our high tunnels had grown to about a foot and then got nailed. Fortunately, these canes are replaced by new canes, so the damage wasn’t devastating for the long haul. The damage, if not noticed could be mistaken for some sort of disease, but the difference is that the plants grow vigorously otherwise, and the damage is all at the same location on the plants throughout the planting.

For more detailed information go to Appendix A of Mid Atlantic Berry Guide Guide

Spread the Word: “Killer” Hornet NOT Found in the Northeastern U.S.

By, Michelle Infante-Casella, Agricultural Agent/Professor, RCE of Gloucester Co. and William Bamka, Agricultural Agent/Associate Professor, RCE of Burlington Co.

Although media reports have triggered panic over the Asian giant hornet (Vespa mandarinia), there are no reports this pest is present anywhere else in North America besides the Pacific Northwest. Rutgers Cooperative Extension, Agriculture and Natural Resource personnel have received inquiries to identify hornets found by the public. In New Jersey, Rutgers Cooperative Extension county offices have not identified any submitted specimens to be the Asian Giant Hornet. The Asian giant hornet has only had confirmed sightings in Washington State and British Columbia, Canada.

“The species has not yet been detected this spring in Washington State or the British Columbia or anywhere else on the West Coast”, said Professor Dina M. Fonseca, director of the Center for Vector Biology in the Department Entomology in the School of Environmental and Biological Sciences at Rutgers–New Brunswick. “We do not know how the species arrived in the United States but it is important to not overreact.”

Washington State University’s information on the Asian giant hornet confirmed the first U.S. sighting of this hornet in the wild. The first two specimens were found in Nanaimo and White Rock, British Columbia, Canada in fall of 2019.

The hornets were reported to be attacking colonies of honeybees in Washington State. The Asian Giant Hornet is known to aggressively attack honeybees and can destroy entire honeybee colonies. Washington State University recently published an extensive fact sheet with identification and guidance for the public. According to the WSU Pest Alert, Asian Giant Hornets are not generally aggressive towards people, but may sting when threatened.

“The Asian giant hornet is unlikely to be present in New Jersey,” Fonseca said. “while citizens in the Pacific Northwest can help detect any emerging hornets this spring, which is critical for its control, the indiscriminate killing of bees, wasps or other hornet lookalikes, would be detrimental because of beneficial roles these insects provide as plant pollinators and predators of agricultural pests.”

An insect that looks similar and can be confused for the Asian giant hornet is the Cicada killer wasp (Sphecius speciosus). They large solitary  wasps found throughout the U.S. and burrow holes in the soil. Even with their large size, dangerous appearance and “dive-bombing” habit, adult Cicada killer wasps rarely come in contact with people and it is rare they will sting. The males of this species will make “dive-bombing” flight patterns, but do not have a stinger and an attack would not result in a sting. The female’s tubular egg-laying structure on the rear end can function as a very weak stinger. Her mild sting is similar to a slight pin scratch and is not considered by most people to be painful. Rutgers Cooperative Extension has more information on the Cicada Killer Wasp and other bees and wasps.

wasps found throughout the U.S. and burrow holes in the soil. Even with their large size, dangerous appearance and “dive-bombing” habit, adult Cicada killer wasps rarely come in contact with people and it is rare they will sting. The males of this species will make “dive-bombing” flight patterns, but do not have a stinger and an attack would not result in a sting. The female’s tubular egg-laying structure on the rear end can function as a very weak stinger. Her mild sting is similar to a slight pin scratch and is not considered by most people to be painful. Rutgers Cooperative Extension has more information on the Cicada Killer Wasp and other bees and wasps.

As more information comes out regarding the Asian giant hornet, it is best to pay attention to where this insect has been confirmed and how far it has spread. It is most likely that the Asian giant hornet would first spread and be reported in surrounding areas bordering Washington State and British Columbia, Canada before any reports would occur on the East Coast. Knowing this information may help to calm fears when seeing other hornets and wasps. As always, take precautions and avoid contact with stinging insects. For identification and recommendations contact your local county Rutgers Cooperative Extension office.

Sourcing Local NJ Farm Products and Concerns of Food Insecurity

By Michelle Infante-Casella and Stephen Komar, Agricultural Agents-Rutgers Cooperative Extension

Where does food come from? Does the U.S. produce enough food to feed all Americans? Let’s stop right there for a minute and go back almost 5 decades.

In the 1970’s gasoline and other energy prices soared causing an American economic crisis. Our country was reliant on foreign oil sources. The US economy struggled, unemployment rates soared, and uncertainties prevailed. Yes, fuel is necessary for transporting people, moving products, for industrial processes and heating homes. However, Americans adapted and made changes to their habits to adjust to the shock of high-energy prices. These changes presented many challenges, but we persevered and over-time the U.S. tapped into domestic resources and the energy industry developed technologies to make us less dependent on foreign energy.

Let’s move ahead to today. This time it is not energy supply at risk, it is literally human lives that are being impacted by a worldwide pandemic. Once again uncertainties – this time food supply and safety are at the top of the list and causing anxiety for many households. Again, the consumer has adapted their preferences and habits in response to this new challenge. Today, consumers still desire fresh, healthy food, but are adapting their shopping habits to include, social distancing, shopping online and other methods to meet their dietary needs.

Going back to our original question, ‘Where does food come from?” To those in the agricultural industry the answer is obvious, but where our food comes from is often not considered by many Americans. The New Jersey Farm Bureau coined the slogan, “No Farmers, No Food”. But how can our farmers meet the changing demands of the consumer in response to the Coronavirus pandemic? Just like the American consumer, New Jersey farmers are changing the way they provide delicious, locally produced food, directly to the consumer.

Let’s face it – everyone enjoys visiting a local farm or farmers market. Not only can customers purchase some of the freshest fruits, vegetables and other products directly from the farmers who produced them, they can enjoy spending some time in the beautiful outdoors. Although most people are familiar with the traditional roadside farm stand, there are several unique products being sold by New Jersey’s innovative farmers. Everything from farm-fresh cheeses to locally raised meats like beef and pork, locally produced beverages, salsa and jellies, to farm-fresh poultry products are being produced right in your backyard. Many local farmers have incorporated Center for Disease Control guidelines including enhanced food safety, social distancing and other precautions to help ensure consumer safety. Some farmers are now offering a variety of ordering and payment options and even providing prepackaged delivery to your vehicle curb-side or to your home.

A CSA or community-supported agriculture is a great way to share in the experience of a local farmer. Much like the stock market, CSA members pay a fee in exchange for a “share” of a farmer’s crop. In exchange for their investment in the farming operation, members receive a percentage of the annual harvest while gaining the satisfaction of knowing where their food was produced and watching it come to fruition throughout the growing season. CSA members are rewarded with delicious yields and excellent returns on their investment in the form of farm-fresh products. Some innovative producers are providing virtual tours of their farms to give consumers the on-farm experience from the comfort of their homes. To learn more about CSAs check out the Rutgers Cooperative Extension fact sheet, Community Supported Agriculture: A Farmer’s Overview.

To help get the word out about New Jersey agricultural products some resources are available. The public can use the Find Jersey Fresh webpage or the NJ Farm Bureau webpage Local Farms – Local Food to find nearby farms with retail markets. Additionally, using your own social media pages and other outlets can attract customers. Farming is an essential industry and everyone depends on farmers to provide food. NO FARMERS NO FOOD.

NJ Department of Agriculture Issues Burn Permit for Frost Protection – Thru May 11

New Jersey Department of Agriculture has issued a notice concerning open burning due to colder spring overnight temperatures presently forecasted for areas of New Jersey from Thursday, May 7 through Monday, May 11, 2020, which could adversely affect fruit, vegetable, and floriculture crops in bloom or near bloom around the state. For details read below the links.

Note: The NJDEP and New Jersey Forest Fire Service caution all farmers and agriculture businesses with respect to the use of open burning in high wind velocity conditions. Please take note that farmers are encouraged to utilize smudge pots is warming as necessary during higher wind conditions. Use of open burning when wind velocity is greater than 5mph is strictly prohibited, may contribute to wildfire risk, and can carry significant penalties. [Read more…]

Weather Conditions and Herbicide Performances

Temperature and Herbicide Performance

With air temperatures remaining relatively low this spring, growers have asked about how temperature may affect the efficacy of herbicide applications. The effect of cool temperatures on weed control efficacy will depend on the type of herbicide application, the rate applied, and the physiological status of the target weed.

Summer annual weeds such as lambsquarters or crabgrass require good soil moisture and soil temperatures between 60 and 70F to start the germination process. It is important for preemergence applications to be effective that residual herbicides are applied before soil reaches this optimum temperature range. Of course, herbicides should never be applied on frozen ground. However, cool and wet weather can increase the potential for crop injury with preemergence herbicides because of slower herbicide metabolization by the crop.

Grass and broadleaf weeds are controlled more effectively when plants are actively growing. The ideal air temperature for applying most post-emergence herbicides is between 65°F and 85°F. At lower temperature, weed control will be slower, especially with systemic herbicides such as glyphosate, Poast, Select, or Sandea that are more slowly absorbed and translocated by the weeds compared to applications at higher temperatures. Also, slower herbicide uptake by the weeds will increase the required rainfast period and slows the development of herbicide symptoms on the plants. Weeds that have been damaged (by mechanical equipment for example) or that are under stress (drought, water excess) at the time of herbicide application or before herbicide has properly translocated will not be properly controlled. Reduced herbicide rate treatments are less likely to provide acceptable control under adverse conditions than when plants are actively growing. Thus, it is best to avoid applications of postemergence herbicides during periods of cool temperatures (<40°F at night; <55°F during the day).

High temperatures increase the loss of volatile herbicides. 2,4-D ester or dicamba will rapidly evaporate at temperatures above 80°F, causing. The use of such ester formulations should be restricted to fall, winter, and early spring because sensitive plants are not present and lower temperatures reduce vapor drift hazard.

Adjuvants may also affect crop safety and weed control. Oil additives may increase risk of crop injury but may be necessary for greatest weed control. Refer to each herbicide label for specific information on adjuvant use during stress conditions. Use an oil additive if risk of crop injury is acceptable for those herbicides that allow use.

Ideally, you should be waiting for the right conditions to apply the herbicide. However, if weeds are at growth stage that require a rapid intervention, select a herbicide with excellent efficacy for controlling your target weeds. Remember that the efficacy pf postemergence applications is mainly dictated by weed size… spraying weeds beyond the size range recommended on the label will result in porr weed control.

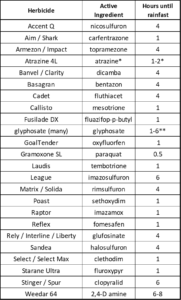

Rainfast Period

The rainfast period is the minimal period of time that must elapse between herbicide application and subsequent rainfall to ensure good postemergence herbicide performance. Generally, herbicide rainfast ratings are based on good growing conditions (table 1). Poor conditions may require a longer interval between application and any rainfall to ensure adequate herbicide translocation within the weed before the herbicide is washed off. For many herbicides, any amount of rainfall soon after spraying has the potential to reduce absorption, translocation, and subsequent weed control. If you apply herbicide and it rains before it’s rainfast, herbicide performance will be reduced.

Table 1. Rainfast time for postemergence herbicides commonly used in New Jersey Specialty Crops.

*Rainfall will improve control from root uptake.

**Rainfall within 6 hr. after application may reduce effectiveness. Heavy rainfall within 2 hours after application may wash the chemical off foliage and a repeat treatment may be required.